Construction

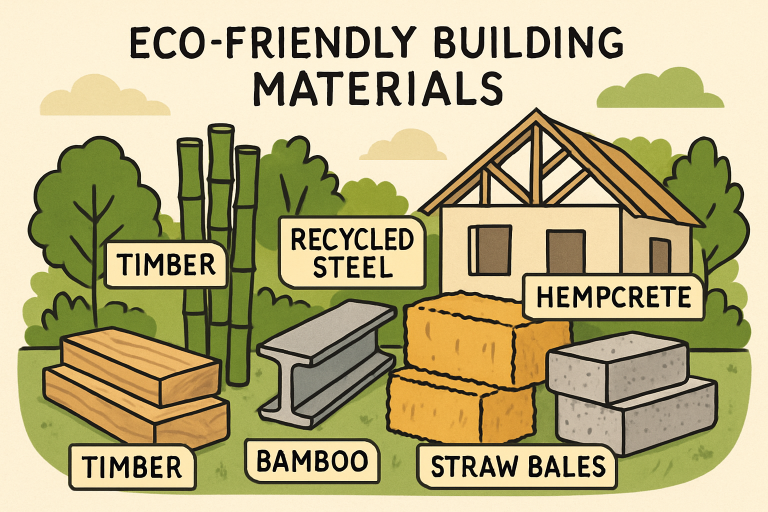

Eco-Friendly Building Materials for Modern Construction

Key Takeaways

- Utilizing sustainable materials can significantly lower a building’s carbon footprint.

- Innovative materials, such as cross-laminated timber and hempcrete, offer both environmental and structural benefits.

- Adopting eco-friendly materials can lead to cost savings and improved energy efficiency over time.

The construction industry is undergoing a significant shift as architects, builders, and homeowners are increasingly prioritizing sustainability. By adopting eco-friendly building materials, modern construction projects can reduce their environmental impact, enhance energy efficiency, and improve the health and comfort of occupants. Whether revitalizing older properties or pursuing new builds, a restoration specialist can help integrate these materials into any project for maximum benefits.

The shift to greener construction is both environmentally and practically beneficial, driven by rising energy costs and climate concerns. Materials like engineered timber, bio-composites, and recycled products are renewable, durable, and serve multiple purposes, from lowering carbon footprints to optimizing resources. Eco-friendly materials are used in everything from small upgrades to large projects, making a significant industry impact. These green options are resilient, efficient, and cost-effective, reducing waste, speeding up construction, and lowering utility bills over time. This shift is a key step toward a healthier, sustainable built environment for future generations.

Cross-Laminated Timber (CLT)

Cross-laminated timber (CLT) is revolutionizing the sustainable building industry. This engineered wood product consists of multiple layers of timber stacked perpendicular to one another and bonded with adhesives. The result is a panel with remarkable strength, stability, and load-bearing capacity that rivals traditional steel or concrete. CLT is a boon for mid-rise and high-rise construction, providing not just structural integrity but also acting as a carbon sink. Throughout their life cycles, CLT buildings retain the CO₂ that trees absorbed while growing, effectively locking away greenhouse gases. Beyond environmental advantages, CLT offers rapid assembly, reduced onsite waste, and supports responsible forestry practices.

Hempcrete

Hempcrete is a lightweight, bio-composite made from the inner woody fibers of the hemp plant mixed with a lime-based binder. It is lauded for its ability to absorb carbon dioxide both during growth and curing, making it one of the most sustainable building options on the market. Although not load-bearing, hempcrete serves as impeccable thermal insulation, reducing energy consumption and maintaining consistent indoor temperatures. It’s an airtight, monolithic structure that supports improved energy efficiency and indoor comfort while drastically minimizing heat loss. New research into biocomposites is validating hempcrete’s quality as an insulator and eco-conscious choice in both residential and commercial construction.

Bamboo

Bamboo is earning its reputation as the “green steel” due to its exceptional tensile strength and rapid regrowth cycle. Unlike most hardwoods, bamboo can be harvested within three to five years and continues to grow even after it has been cut. Its applications range from structural framing and flooring to wall panels and cabinetry, providing a sustainable alternative to conventional hardwoods. With a unique pattern and color, bamboo fits beautifully within both modern and classic design schemes. The growing global demand for bamboo construction underlines its credibility as a formidable green building material.

Recycled Steel

Steel remains a backbone of modern infrastructure, but its production is notoriously energy-intensive. Recycled steel, however, provides a compelling green solution. As one of the world’s most recycled materials, steel can be reprocessed numerous times without compromising its quality. Using recycled steel in new construction projects minimizes waste, drastically reduces energy consumption compared to producing virgin steel, and decreases landfill demand. From framing to roofing, recycled steel offers both sustainability and durability, supporting a closed-loop supply chain in the building sector.

Plant-Based Polyurethane Foam

The demand for effective insulation solutions has propelled innovation in plant-based polyurethane foams. Derived from renewable resources such as soybeans and castor oil, these foams match the insulating properties of traditional petroleum-based equivalents, but with a significantly improved environmental profile. Besides providing excellent thermal resistance for walls, roofs, and HVAC systems, plant-based polyurethane foams emit fewer volatile organic compounds (VOCs), which supports better indoor air quality and reduces reliance on fossil fuels. As sustainable building codes tighten, plant-based insulators are quickly gaining mainstream acceptance.

Straw Bales

Reviving an age-old technique, straw bale construction is making waves in today’s eco-conscious building landscape. Tightly packed and finished with plaster or render, straw bales deliver exceptional insulation properties while keeping embodied energy and costs low. They are biodegradable, widely accessible, and often sourced locally—further reducing emissions associated with transportation. In the 21st century, straw bale designs have been modernized for use in passive houses, eco-friendly tiny homes, and even larger commercial spaces, providing a renewable, natural alternative that aligns with green building standards.

Conclusion

Integrating eco-friendly building materials such as cross-laminated timber, hempcrete, bamboo, recycled steel, plant-based polyurethane foam, and straw bales is vital for advancing sustainable construction. These materials deliver clear environmental, economic, and health benefits, ushering in an era where green building is not just a trend but an essential component of modern construction. As more builders and property owners adopt these innovations, the industry will continue to move towards a more sustainable and resilient future.