Business

How Humidity Testing Is Shaping Product Reliability

Key Takeaways

- Humidity is a major environmental factor affecting the integrity and performance of products across multiple industries.

- Integrating rigorous humidity testing into quality control processes helps reduce failures and increase durability.

- Technological advancements in humidity measurement enhance the accuracy and usefulness of product testing.

- Industries from electronics to pharmaceuticals rely on robust humidity protocols for regulatory compliance and consumer safety.

- Strategic implementation of humidity testing supports long-term product success and brand protection.

Table of Contents

- Understanding the Impact of Humidity on Products

- The Role of Humidity Testing in Quality Assurance

- Innovative Approaches to Humidity Testing

- Case Studies: Real-World Applications

- Best Practices for Implementing Humidity Testing

- Conclusion

Understanding the Impact of Humidity on Products

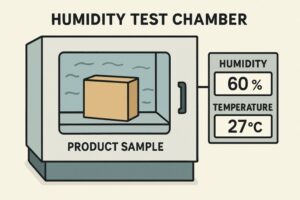

Humidity is more than just an environmental nuisance—it plays a critical role in the performance and longevity of finished goods. Elevated moisture levels can cause rapid corrosion in metals, deteriorate polymers, and disrupt the function of sensitive electronics. Even minor fluctuations in humidity may result in performance failures that only become apparent after deployment, leading to costly recalls and negative customer experiences. Many companies rely on advanced humidity control chamber systems to address these challenges for development and testing.

Industries like pharmaceuticals are particularly vulnerable to moisture, as drugs and active ingredients can degrade quickly without diligent environmental control. Exposure to humidity may shorten shelf life, compromise effectiveness, and introduce health and safety risks. Similarly, the automotive sector faces seal failures and electronic malfunctions caused by condensation and moisture ingress.

Humidity affects technical specifications and often defines a product’s real-world reliability. Understanding these risks is the first step toward establishing comprehensive quality assurance protocols that proactively protect end-users and brand reputation.

Moreover, increased awareness of environmental variables has led to changes in international manufacturing standards and regulations. As sustainability goals rise and global shipping expands, testing for climate resilience is now a universal best practice for leading brands. More background on the growing emphasis on environmental testing standards can be found at the National Institute of Standards and Technology (NIST).

The Role of Humidity Testing in Quality Assurance

Product recalls and unexpected failures are expensive, both financially and in terms of brand reputation. Humidity testing allows manufacturers to accurately simulate the long-term effects of exposure to variable moisture levels, reducing the risk of market surprises and warranty claims. By carefully monitoring product reactions in controlled humidity conditions, weak points can be identified and remedied early in the product life cycle.

Systematic humidity testing supports a proactive approach by:

- Enhancing Product Longevity: Manufacturers gain insights to refine material selection, assembly design, and protective coatings, resulting in longer-lasting goods.

- Reducing Recalls and Failures: Detecting and correcting defects before they reach customers lessens the likelihood of recall events or critical failures in the field.

- Ensuring Compliance: Meeting the climate resilience regulatory standards now required for market access across many regions and industries.

Innovative Approaches to Humidity Testing

The rise of precision electronics and globalized shipping has triggered greater investment in more innovative humidity monitoring systems. State-of-the-art sensor technologies now deliver granular, real-time temperature and moisture content data, improving the reliability of accelerated aging tests and failure mode simulations. These data-driven tools enable engineers and quality managers to run advanced analytics, predict failure rates, and optimize design parameters for real-world use cases.

Incorporating machine learning and cloud-based platforms also means manufacturers can identify subtle trends and anomalies faster than ever—transforming environmental testing from a manual quality control step into a powerful, predictive strategy for entire product lines.

Case Studies: Real-World Applications

- Electronics: Through humidity exposure tests, device makers have traced short circuit issues and surface corrosion back to excessive moisture exposure, enabling the development of robust conformal coatings and innovative packaging solutions.

- Pharmaceuticals: Customized packaging and moisture-absorbing inserts, guided by rigorous trial results, have extended drug shelf lives, ensuring that patients receive effective, stable medication across climates and geographies.

- Automotive: Testing in climate chambers has revealed latent design vulnerabilities for seal integrity and sensor performance. This allows manufacturers to fine-tune assemblies for various humid environments, from coastal regions to arid deserts.

These applications underscore how ongoing investment in humidity testing translates into measurable improvements for manufacturers and consumers.

Best Practices for Implementing Humidity Testing

- Invest in Quality Equipment: Utilize precision humidity chambers and calibrated sensors to create controlled, consistent test settings for complex products and assemblies.

- Regular Calibration: Accurate testing depends on equipment integrity. Scheduled calibration and periodic maintenance of chambers and sensors ensure that data remains reliable year after year.

- Comprehensive Testing Protocols: Define test protocols that accurately represent the physical environments in which products will be used, simulating gradual and extreme humidity fluctuations.

- Data Analysis: Use digital data analysis tools to interpret correlations between humidity exposure and performance, guiding product design and material selection with objective evidence rather than guesswork.

Following these steps ensures organizations are equipped to meet today’s high standards and exceed them as product reliability expectations rise in increasingly complex markets.

Conclusion

Humidity testing has become an essential practice for manufacturers dedicated to delivering reliable and long-lasting products. In today’s environment of heightened consumer expectations and stricter industry regulations, overlooking this step can result in product failures, costly recalls, and damage to brand reputation. By integrating humidity testing into quality assurance processes, organizations can identify vulnerabilities early, improve durability, and ensure compliance with evolving standards. Advances in testing technology have made the process more efficient, affordable, and data-driven, allowing companies to monitor and respond to environmental stressors with greater precision. Beyond meeting requirements, prioritizing humidity control demonstrates a clear commitment to excellence, positioning manufacturers as leaders in quality and innovation. This proactive approach safeguards product performance and strengthens consumer trust, making it a valuable investment in long-term brand credibility, customer loyalty, and market competitiveness.