Business

Smart Ways in Modern Warehouse Automation Design

When the companies’ facilities are growing, they might start to manage larger inventories while keeping their operations more manageable. This is where the application of automated systems can immensely help them because everything can become more efficient. Businesses of every size can identify the location of certain products faster, and everything can become more predictable.

More importantly, companies are now trying to reduce risks for their workers when they work with equipment like safety barriers that you can find more info here. Many operators are now working on traffic lane markings to reduce instances of collisions, and safety drills are often regularly performed so everyone knows how to evacuate when there are natural disasters.

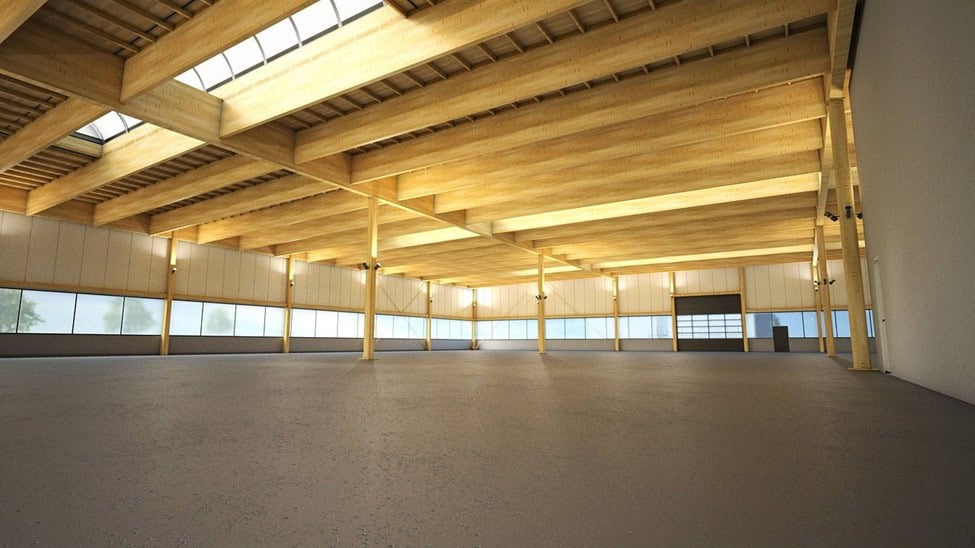

What Does an Effective Layout Mean?

Factories are now planning their layouts well, so items can be safely sorted in each zone. Everyone will have walkways for people, while the machines have their own routes. There’s a certain path that the forklifts can follow when certain products arrive in the warehouse, and this makes everything more efficient.

Bottlenecks can be prevented when there’s proper layout design, and it can help teams speed up their work during peak hours. Even some small adjustments to the width of the aisle can enable everyone to access goods in the best way possible.

The right team can design a safe environment where they can separate various areas, like packing and receiving, for clearer boundaries. They specialize in warehouse automation designs that can accommodate new machinery and avoid traffic in the workplace. They can also activate scanners that work constantly to identify dangerous situations in the workplace.

Enhance Safety Through Structured Organization

Companies that prioritize their workers’ protection can lower the risks of accidents, and it enables the team to focus on their jobs. Do this by adding pathways where the pedestrians are separated from moving machines.

Excellent designs also encourage routine checking to see if the machinery is parked in a safe area with enough room for people’s movement. Frequent inspections can also extend the lifespan of these vehicles and make sure that they continue to work well as production goes up. It can also prevent operational shutdowns, especially if they stay efficient.

Maximize your Space Without Overcrowding

In a facility, you need more area in order to avoid cluttered zones, and the best teams will generally recommend a vertical storage system if necessary. They may apply adaptable shelves so you can fit more inventory, and the movement of everyone becomes less stressful.

Smart spacing is also easier to clean, and if there’s dust, it can be removed faster by the maintenance crew. It will result in a tidy environment that reduces the risks of fires, and when everything is within reach, orders can be fulfilled with minimal friction.

Integrate Automation Tools for Smoother Workflows

There are a lot of systems that can automate processes, so automated tasks can be handled effectively. It can involve the conveyor belts that you can find info in this link https://www.merriam-webster.com/dictionary/conveyor%20belt or robotic arms that weld various pieces together in a factory. When these are integrated correctly, they are going to make the work faster.

They also provide a wealth of benefits as they can reduce instances of human errors. Most machines are consistent when it comes to the quality of the products that they make. If you install tracking software as an addition, you can monitor their movements in real time, and this is going to mean better results.

How Strong Planning Supports Faster Fulfillment?

Clients are now expecting speedy delivery of their orders in today’s times, and delays may often discourage them from ordering again. Fortunately, well-planned facilities can structure the tasks according to the demand, and many employees spend less time searching for inventory with the right tools in place.

Fulfillment becomes a more predictable process, and there’s a smoother transition between the zones, so orders can travel through each step without stops. The predictability can improve schedules in manufacturing, and it can strengthen customers’ trust, so they will want to order again.

Building for Longevity and Future Growth

Some facilities will need more flexibility as they grow, and proper planning can help them achieve this. Future expansions are possible without extensive renovations, and this avoids starting from scratch because they can just make some adjustments in the existing structures.

Many designers will also think about the lighting and how it can be made into a more energy-efficient addition, and they will also factor in how workers can work together harmoniously. Investing in these can pay off in the long term, so companies can adapt to the systems without major disruptions.

When people feel that the management is concerned with their safety by adding automated tools that can make their work easier, this can reduce their mental load. They stay calm throughout the day, and they don’t commit mistakes, which can result in better morale.